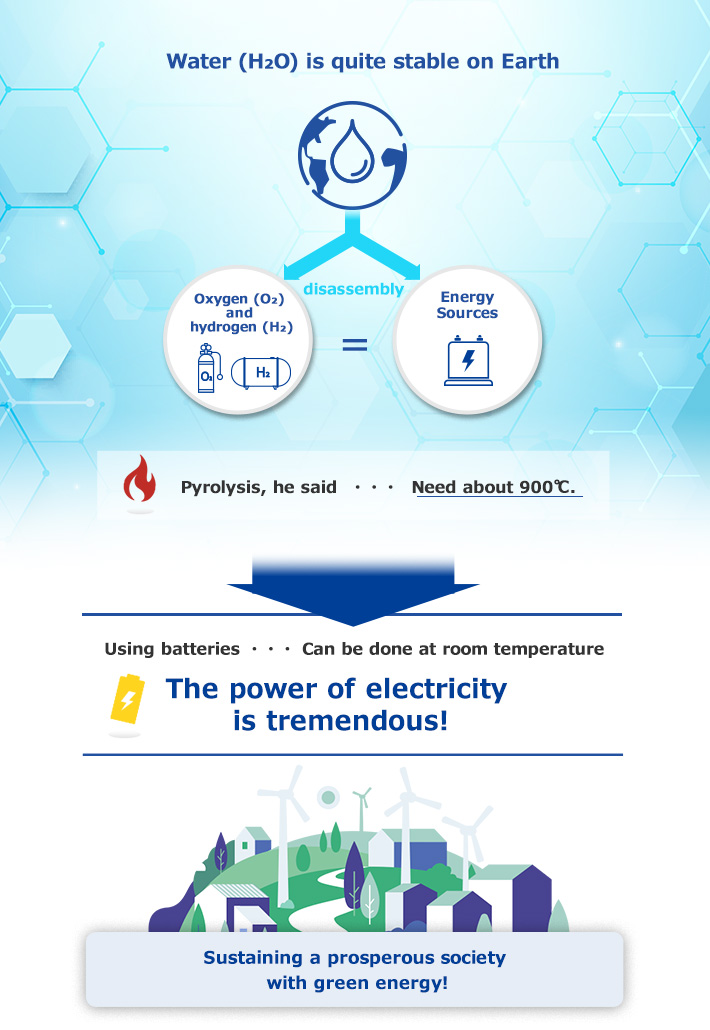

What is electrochemistry?

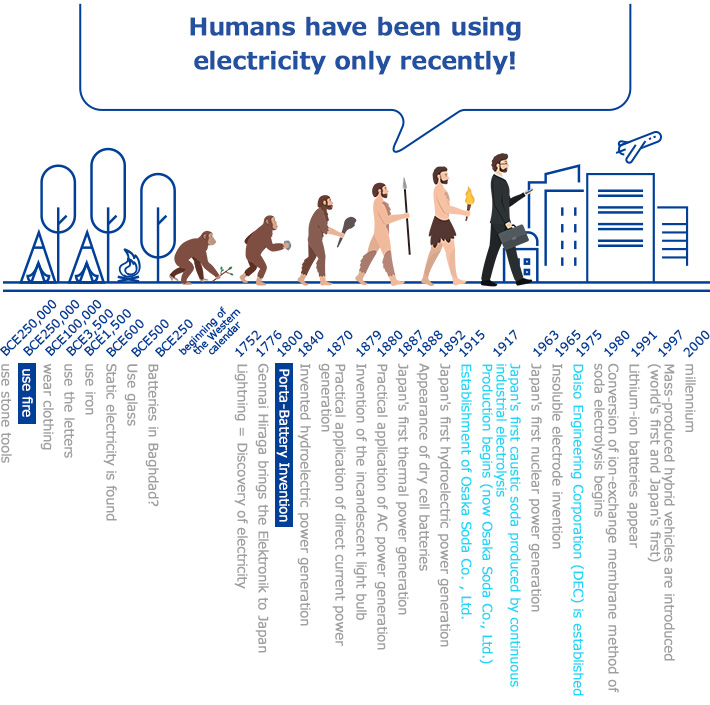

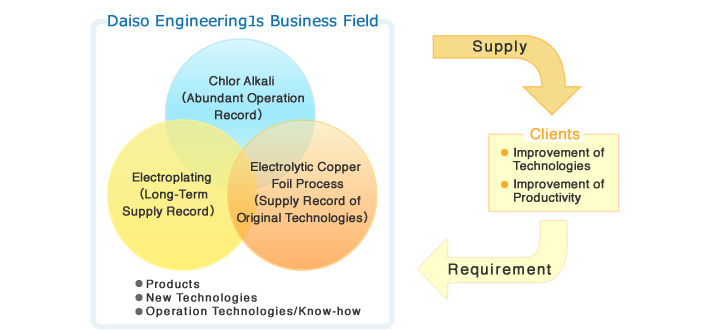

Daiso Engineering Co., Ltd. ("Daiso Engineering") is very proud of the efforts it has continuously made on its 100-year-old salt electrolysis technologies and electrode technologies to meet the ever-expanding needs of chlor alkali operators.

Daiso's chlor alkali operations date back to 1916 when it began operations of the first mercury process electrolysis plant in Kokura, Japan. Ever since then, Osaka Soda Group has contributed to the development of various advanced technologies in

the world of chemical industry.

Daiso Engineering, a wholly-owned subsidiary of OSAKA SODA Co., Ltd. ("Osaka Soda"), has developed its own metal electrode technologies based on its accumulated electrochemical knowledge and electrolysis expertise. It has supplied operators

of various industrial plants worldwide, including those for chlor alkali plants and electroplating plants with a vast range of state-of-art electrodes brand. Those electrodes include those coated with selected active

metal catalysts on

their titanium/nickel substrates.

Daiso Engineering has continually devoted efforts to technical developments and the accumulation of operational expertise related to electrolysis plants and their surrounding facilities with full utilization of the company's commercial production facilities. Thus, users are fully assured of the safety of Osaka Soda Group Engineering's electrodes application to their own commercial production facilities.

In electrogalvanizing steel plants, operations are normally required at a very high current density of more than 100 A/dm2. However, Daiso Engineering has met such market requirements to successfully attain extremely high performance of its electrodes in these plants, and as a result, it has maintained a large market share of more than 80% in Japan.

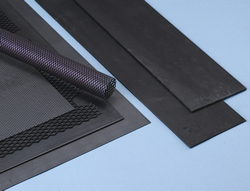

NEOLORDTM (High durability and environmentally compatible safety in a wide range of fields)

Electrodes with catalysts impregnated on base metals such as titanium and nickel are widely used in electrolysis processes, not only in the soda industry. Compared to lead alloy electrodes*, our iridium oxide-based electrodes (=platinum group

metal electrodes) not only reduce electrolysis voltage, but also greatly improve the working environment as they do not generate sludge, facilitate electrolysis bath management, are light in weight, and have no adverse physical effects.

In

addition, our electrodes are highly economical due to their high durability in a variety of electrolysis processes. Furthermore, electrolyzers equipped with our electrodes are also excellent in terms of reducing peripheral equipment maintenance

and waste liquid treatment costs, and we propose and realize manufacturing cost reductions for our customers, thereby contributing to environmental preservation.

Daiso Engineering are capable of making comprehensive technical proposals, including electrode shape design, electrode catalyst selection, and electrolyzer operation, in response to customer requests, and have been favorably received by many customers.

*Lead-alloy electrodes, which have been used for a long time, cause sludge as the catalyst lead alloy peels off or lead compounds during electrolysis, which adversely affects the stable operation of the process. Lead or lead compounds are considered to be harmful to the human body, and the plating industry, as well as other key industries, are taking lead-free measures.